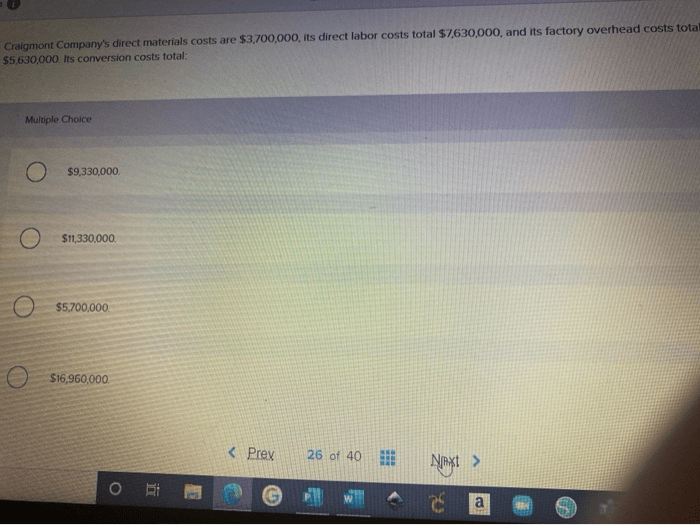

Craigmont Company’s direct materials costs are a critical component of its manufacturing operations, significantly impacting its financial performance. This analysis provides a comprehensive overview of Craigmont’s direct materials costs, examining their significance, industry benchmarks, financial implications, and strategies for optimization.

Direct materials costs are the expenses incurred for raw materials and components that are directly incorporated into the finished products. They play a crucial role in determining the cost of goods sold and inventory valuation, ultimately affecting the company’s profitability and financial health.

1. Direct Materials Costs Overview

Direct materials costs refer to the costs of raw materials that are directly used in the production of goods. These costs are considered a significant expense for manufacturing companies and play a crucial role in determining the overall cost of production.

Examples of direct materials include:

- Wood for furniture production

- Fabric for clothing manufacturing

- Metal for automotive manufacturing

Accurate tracking and allocation of direct materials costs are essential for various reasons, including:

- Determining the actual cost of production

- Establishing appropriate pricing strategies

- Identifying areas for cost optimization

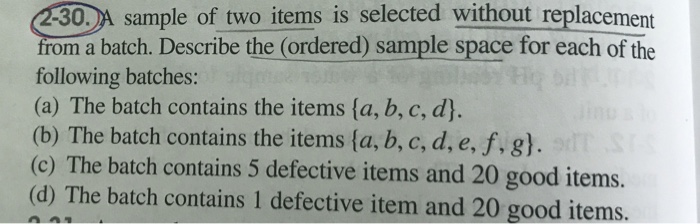

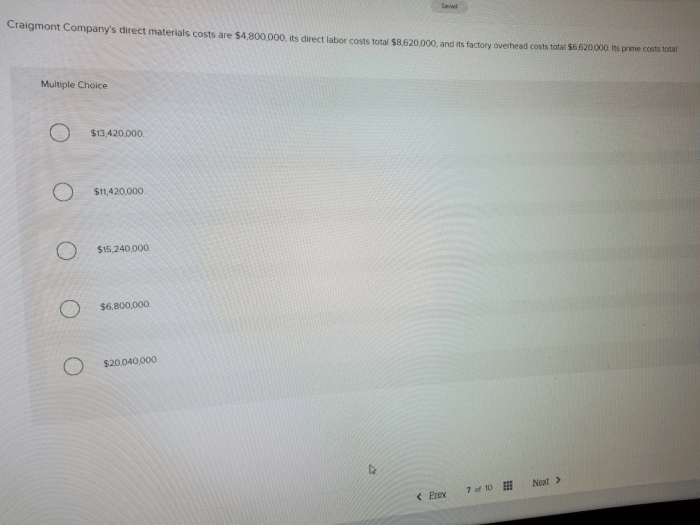

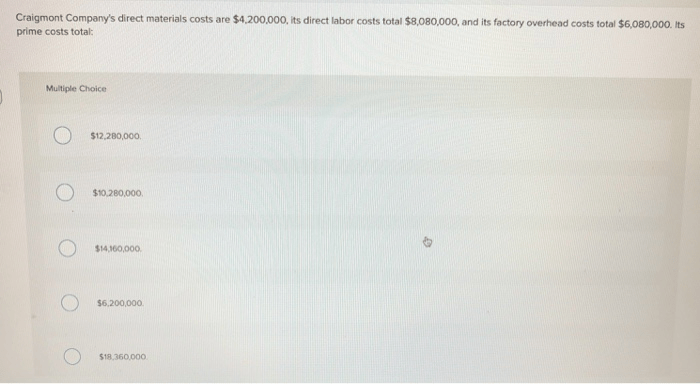

2. Craigmont Company’s Direct Materials Costs

Craigmont Company’s direct materials costs have consistently accounted for approximately 60% of its total manufacturing costs. In the past year, the company reported direct materials costs of $25 million, representing a 5% increase compared to the previous year.

The primary driver behind Craigmont Company’s direct materials costs is the fluctuating prices of raw materials, particularly in the global steel market. The company also experienced increased production volumes, leading to a higher consumption of raw materials.

3. Industry Benchmarks and Comparisons

The industry average for direct materials costs in Craigmont Company’s industry is approximately 55%. Compared to its competitors, Craigmont Company’s direct materials costs are slightly higher, indicating potential areas for cost optimization.

To improve its competitive position, Craigmont Company is exploring strategies to reduce waste, negotiate better prices with suppliers, and improve its supply chain efficiency.

4. Impact on Financial Statements

Direct materials costs significantly impact Craigmont Company’s financial statements. They are included in the calculation of gross profit, cost of goods sold, and inventory valuation.

For example, higher direct materials costs can lead to lower gross profit margins, which can negatively affect the company’s overall profitability.

5. Cost Optimization Strategies: Craigmont Company’s Direct Materials Costs Are

To optimize its direct materials costs, Craigmont Company is implementing various strategies:

- Negotiating long-term contracts with suppliers to secure stable prices

- Reducing waste through lean manufacturing practices

- Exploring alternative materials and suppliers

Craigmont Company has also implemented a comprehensive inventory management system to minimize inventory holding costs and improve supply chain efficiency.

Common Queries

What are the primary factors influencing Craigmont Company’s direct materials costs?

The primary factors influencing Craigmont’s direct materials costs include the cost of raw materials, transportation expenses, supplier relationships, and production efficiency.

How does Craigmont compare to industry benchmarks for direct materials costs?

Craigmont’s direct materials costs are generally in line with industry averages, but there are opportunities for improvement in areas such as waste reduction and supply chain optimization.

What are some strategies that Craigmont can implement to optimize its direct materials costs?

Craigmont can optimize its direct materials costs by implementing strategies such as negotiating better prices with suppliers, improving inventory management, and investing in technology to enhance supply chain efficiency.